Revolutionise Your Excavation Projects

Thank you for your enquiry...

One of our team members will contact you within 24 hours to discuss your requirements and help you specify your Nox Tiltrotator.

In the meantime, we have included some technical specifications below.

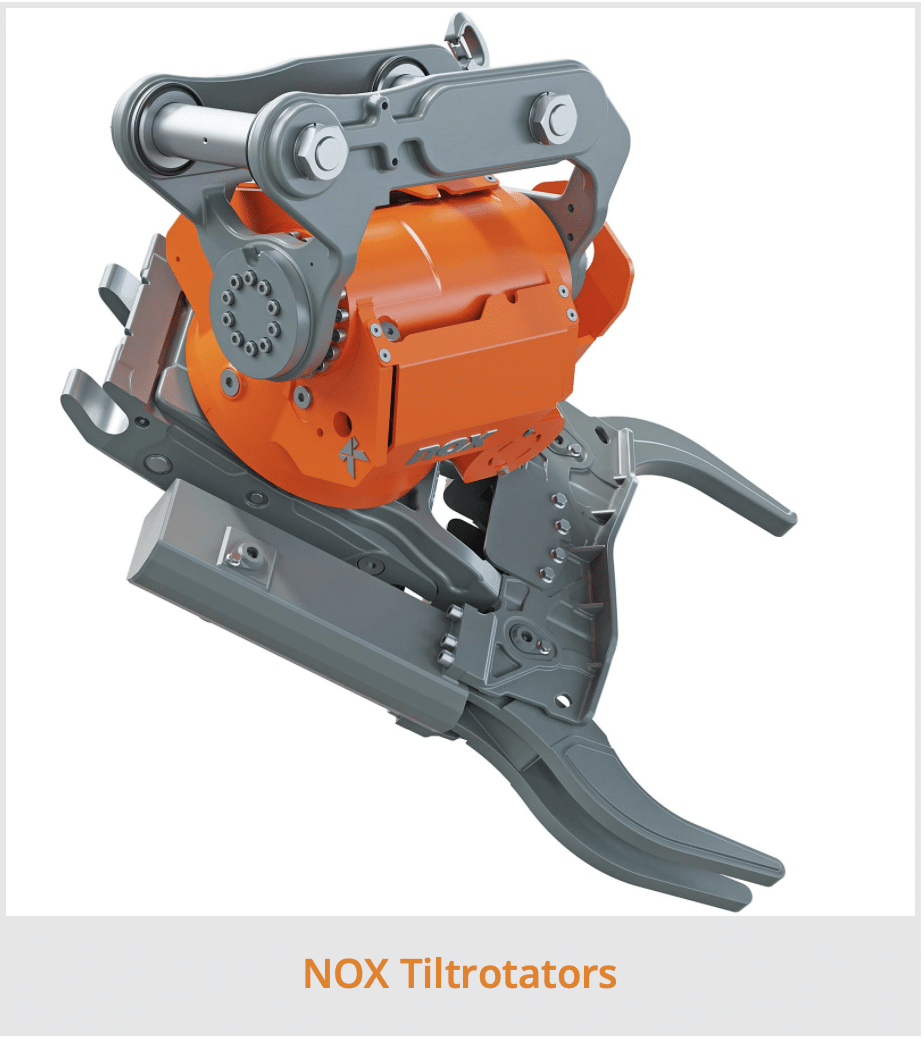

NOX Upper Bracket:

The NOX Tiltrotator can be mounted directly on the excavator arm (direct mount) or as sandwich-design by attaching it to the excavator arm with a quick coupler. Preferably the quick coupler on the excavator arm is the same as the lower quick coupler on the NOX Tiltrotator, however, this is not absolutely necessary.

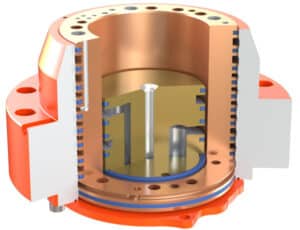

NOX Rotation and Tilt Unit:

The compact design with the fully integrated tilt and rotation unit offers maximum protection against damage. The NOX Tiltrotator has no protruding cylinders or piston rods that can be damaged, which increases reliability. In addition, the low construction ensures a higher breakout force.

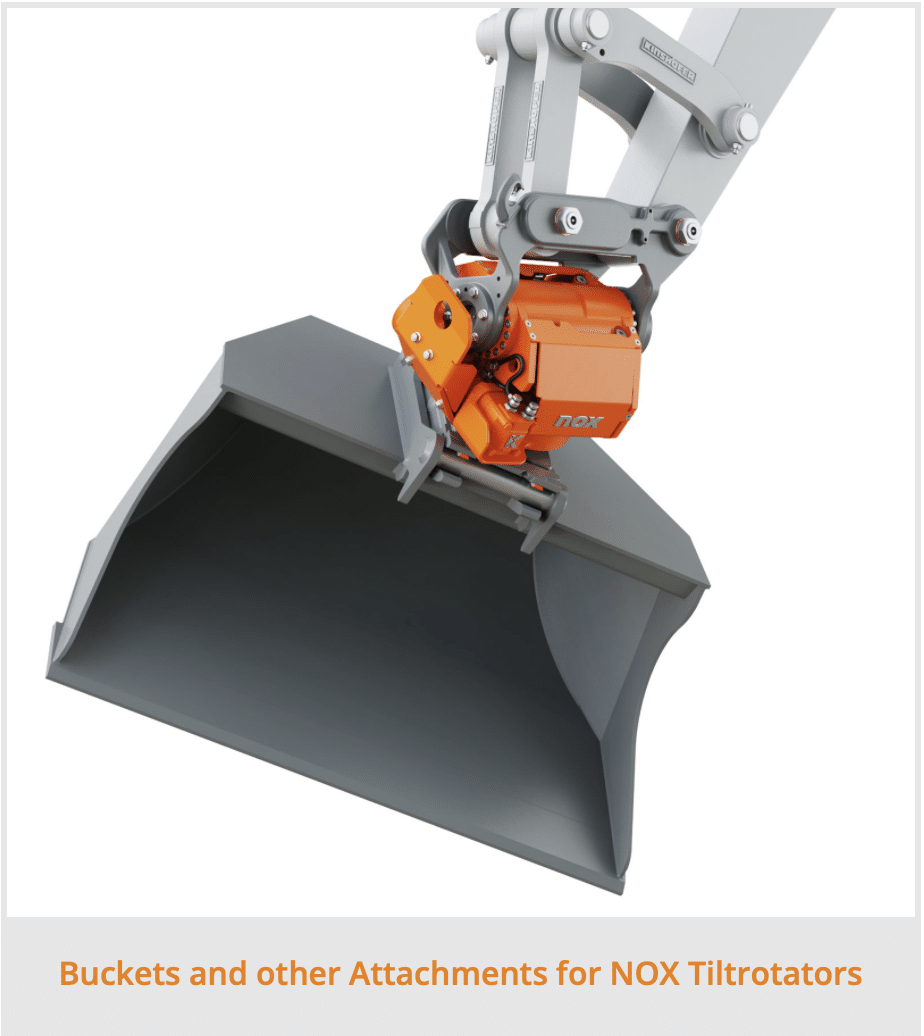

NOX Lower Quick Coupler:

The lower quick coupler on the NOX Tiltrotator enables a safe and quick exchange between the attachments. You can choose between mechanical, hydraulic or fully hydraulic quick change systems.

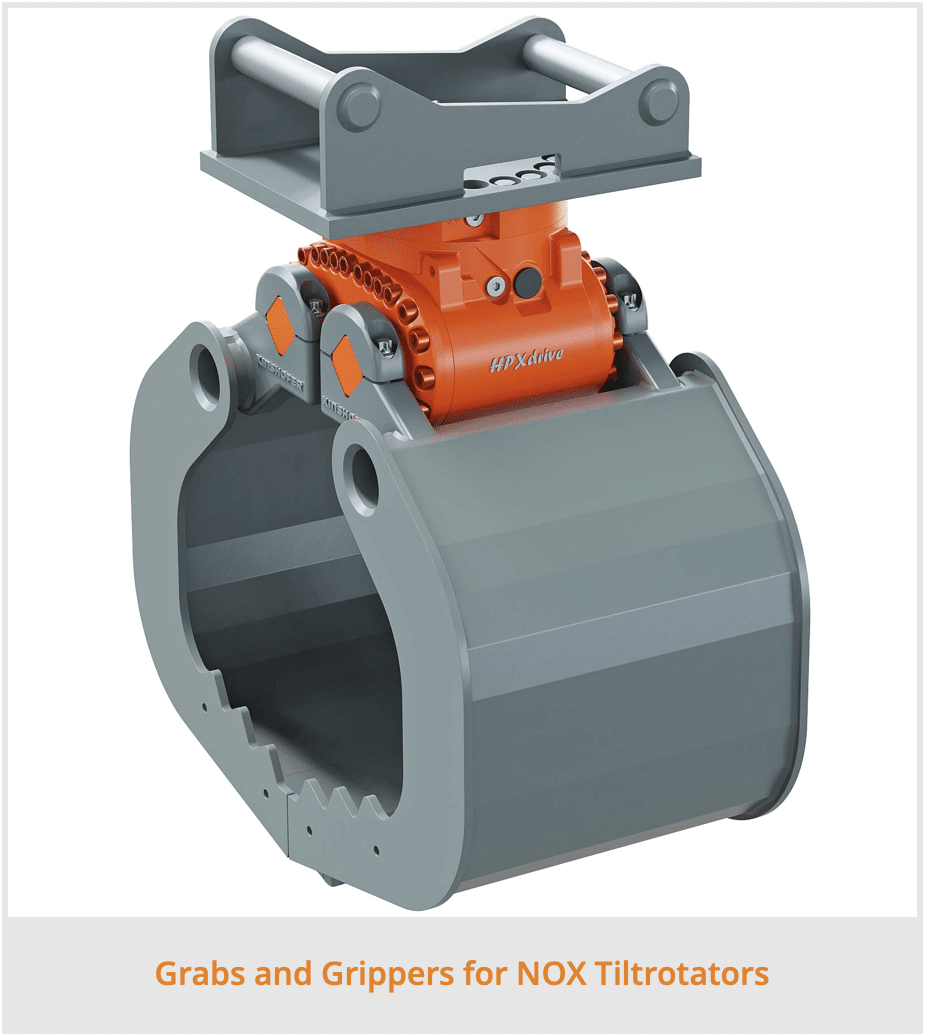

Optional – INTEGRATED GRIPPER TRG:

With the integrated gripper you get an additional attachment for handling poles, tubes and curb stones. The gripper is integrated at the lower quick coupler and does not affect the height or the attachment cross-movement.

Optional – GRIPPER F-H:

The gripper module is also available as a regular attachment version F-H with various adaptations. As with the integrated gripper TRG, materials such as pipes, poles and curbs can be easily handled. The gripper module F-H is picked up like an attachment with the lower quick coupler.

Optional – RAILROAD GRIPPER RR-TRG:

The RR-TRG gripper has been designed especially for heavy duty tasks, such as gripping railroad sleepers or rails. The extremely strong gripper module has been constructed for efficient gripping at a 40° angle. The gripper unit can be removed quickly and easily.

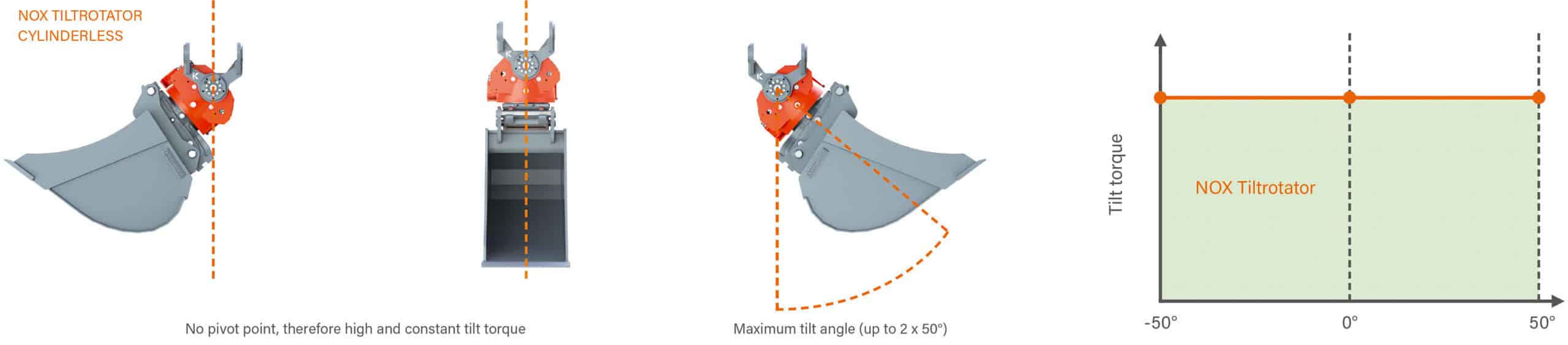

NOX Tilt Torque

Traditional tiltrotators that use cylinders offer only a limited tilt angle and inconsistent tilt torque.

With 360° continuous rotation and a tilt angle of up to 2 x 50°, the NOX system enhances machine functionality, improving operational flexibility and attachment efficiency.

Its cylinderless, ultra-flat drive allows for a low profile and narrow design. The unique elliptical piston, combined with a single gearing system, delivers consistently high tilt torque. The robust cast housing is made from a specially developed alloy, ensuring exceptional stability and long service life, even under the toughest conditions.

Designed for demanding tasks, the NOX drive is extremely durable and features a reliable greasing system, making it low-maintenance and suitable for heavy-duty applications.

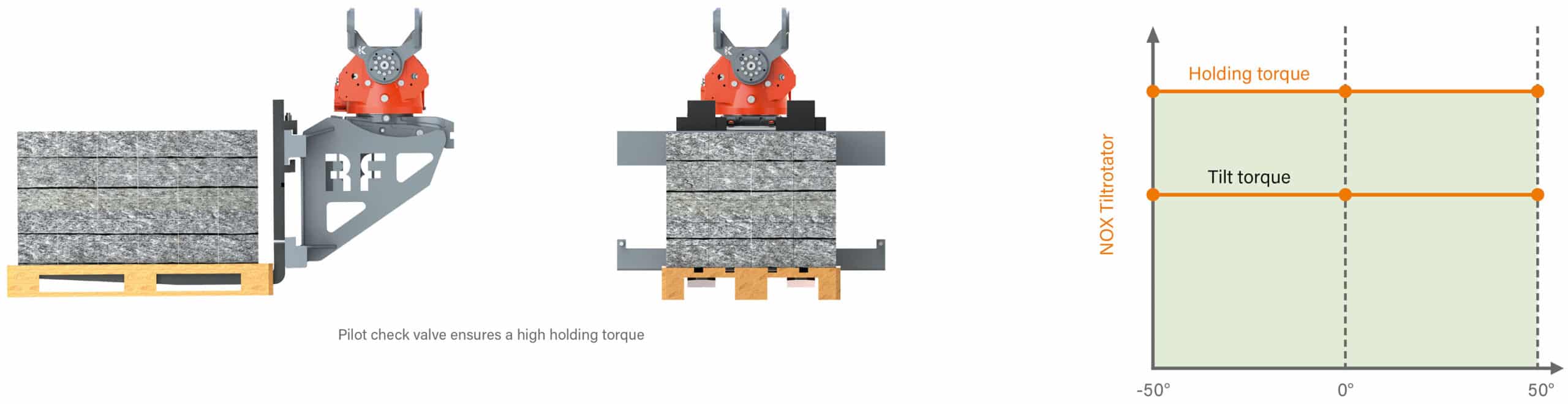

NOX Holding Torque

The NOX Tiltrotator is equipped with counter-balance valves, providing firm load holding in the desired position.

Turn efficiency in your direction!

With using the NOX Tiltrotator, you are not only reducing the need for repositioning your excavator and thus sparing the ground from damage (especially when it comes to landscaping tasks), but you will also speed up your work.

The attachments can be positioned within the complete reach of the boom to work around obstacles. Fast and easy levelling works with a levelling bar can be realised without repositioning the excavator.

Precise setting of curbstones, dosed and accurate filling of trenches with a bucket turned by 90° as well as the handling of different kinds of materials in narrow areas are no problem with the NOX Tiltrotator.

NOX Tiltrotator Specifications

UPPER BRACKET & LOWER QUICK COUPLER

The NOX Tiltrotator can be mounted directly to the excavator arm (direct mount) or it can be »Sandwich« mounted to the excavator by a quick coupler. Preferably, the excavator coupler is the same as the lower quick coupler on the NOX Tiltrotator, but it is not necessarily required. The NOX Tiltrotator can thus be uncoupled and coupled again in no time. The lower quick coupler allows for a safe and fast exchange between attachments.

COMPACT DESIGN

The cylinderless, extremly low and narrow built drive unit allows for very narrow bucket width, that are usually not wider than the excavator boom. Therefore, digging down in deep trenches becomes possible and very easy.

SELFCONTAINED UNIT

The compact design with its fully integrated tilt and rotation unit provides highest safety against damage. There are no protruding cylinders or piston rods that can be damaged, increasing the reliability of the NOX Tiltrotator. In addition, the low design maintains higher breakout forces of the machine.

SAFE WORKING AREA

The increased working radius reduces the need for repositioning your excavator to a minimum. Manual works such as manual digging in the danger zone by a co-worker are not necessary, as these works can be managed from the excavator cabin with the NOX Tiltrotator. The S-Lock quick coupler with front-lock prevents the attachments from falling down unintendedly.

HOUSING

The robust cast housing features a high stability due to a special material alloy, guaranteeing a long life even under the toughest conditions. The integrated motor cover protects the hydraulic motor of the worm drive from damage from below. The quality of our precision components is ensured by 3D coordinate measuring machines with tactile and optical measuring sensors

WORM DRIVE

The oversized worm gear absorbs shock loads with ease. The compact diameter and yet high torque ensures a very slim design, hence keeps the overall width of the NOX Tiltrotator extremely small.

HIGHFLOW SWIVEL

The optional high-flow swivel provides industry-leading flows for attachments that require more flow to operate properly. As an option, an electric rotary unit for quick coupler sensors and attachments with switch valve (mainly in railway construction) can be used.

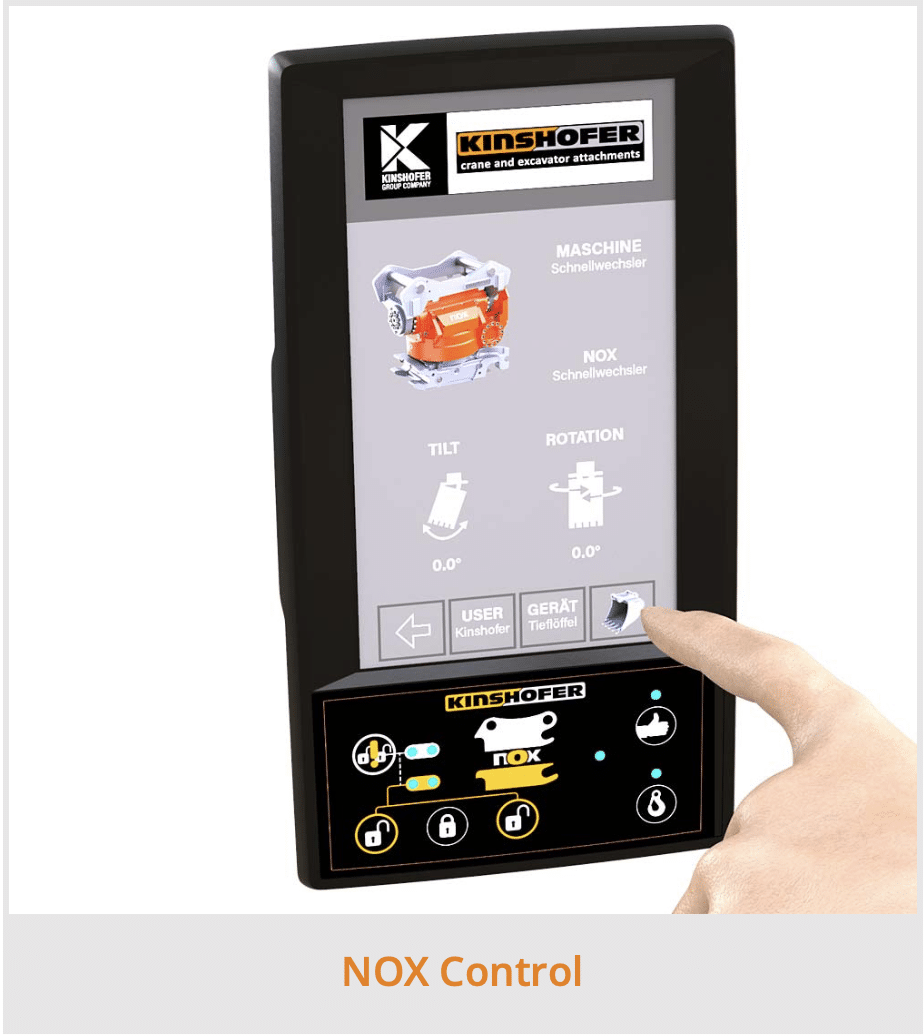

PERFECTLY FITTING CONTROL

Always the right control system depending on the machine‘s hydraulic configuration.